News

Rohm develops a new generation of bipolar MOSFETs that realize ultra-low-conduct resistance

- Author:ROGER

- Release on:2021-06-30

~ Ideal for 12 40V and 60V pressure-resistant products driven by industrial equipment and base station motors ~

Global well-knownsemiconductorManufacturer RoHM (headquartered in Japan, Japan), has developed a built-in with 2 pressure ± 40V and ± 60V MOSFETs and supporting 24V input bipolar MOSFET * 1 "QH8MX5 / SH8MX5 series (NCH + PCH * 2)", very Motors for industrial equipment and base stations (cooling fans) such as FA.

In recent years, in order to support 24V inputs used by industrial equipment and base stations, MOSFETs are used as devices for driving, and the pressure resistance of 40V and 60V is required to take into account the voltage stabilization margin. In addition, in order to further improve the efficiency of the motor and reduce the size, the MOSFET also proposes a lower on-resistance and high speed switching.

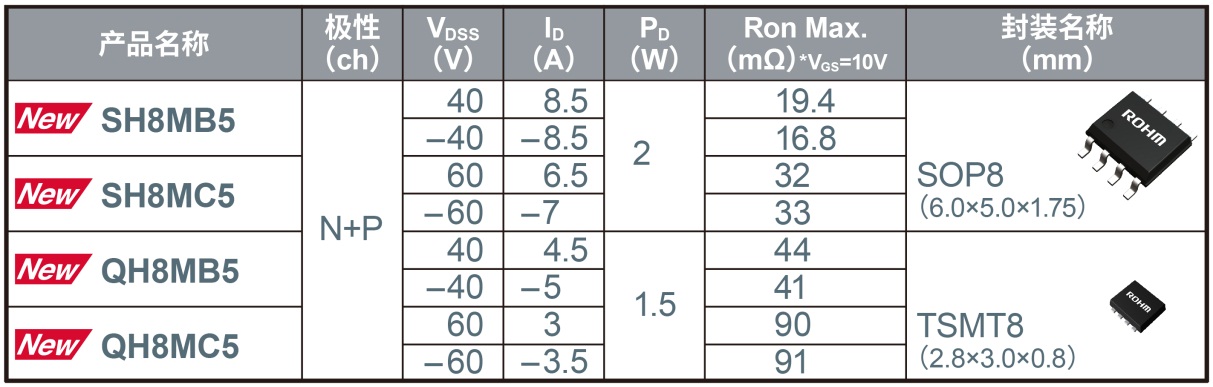

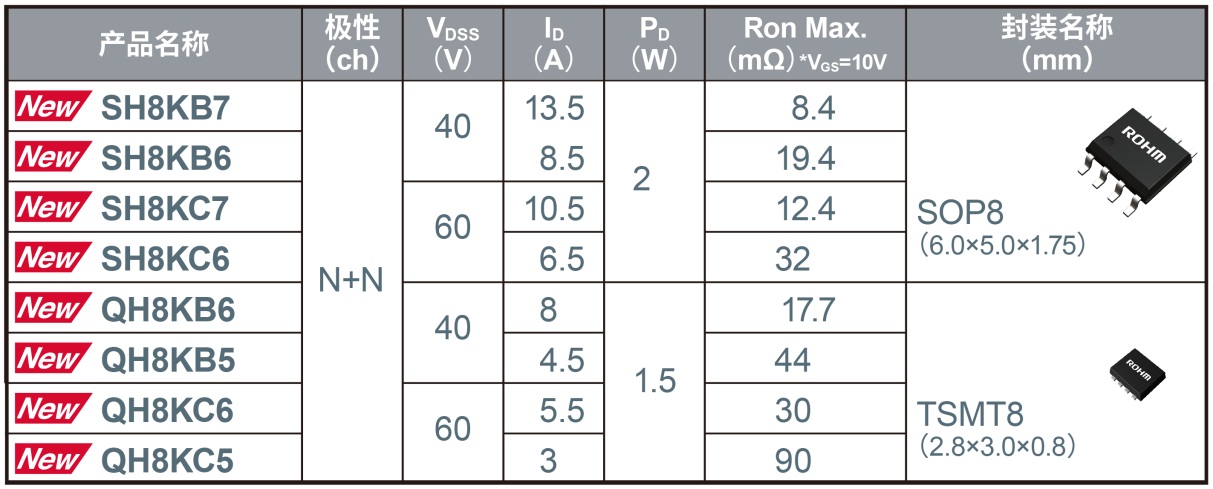

In this context, the RoHM followed the new generation of PCH MOSFET * 2 issued by the end of 2020, and this time I developed the sixth generation 40V and 60V pressure-resistant MOSFETs integrated into the new fine process in NCH. Through this combination, RoHM has a ± 40V and ± 60V withstand voltage levels that support 24V inputs.industryAdvanced NCH + PCH bid MOSFET products. In addition, in order to meet a broader demand, RoHM also develops + 40V and + 60V withstand voltage "QH8KXX / SH8KXX series (NCH + NCH)", and the product lineup has reached 12 models.

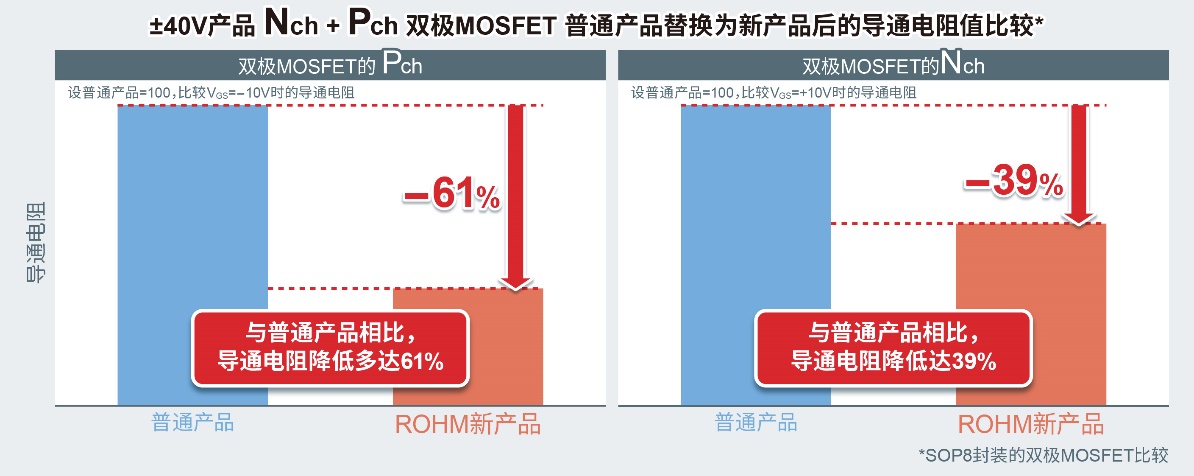

This series of products uses ROHM new processes, realizedindustryUltra-low on-resistance, the on-resistance of ± 40V withdrawal product is less than 61% lower than that of ordinary products (compared to the PCH portion of the bipolar MOSFET), which helps further reduce the power consumption of various devices. In addition, by integrating two devices into a package, it helps to reduce the miniaturization of the device by reducing the mounting area, and help to reduce the time of the device selection (NCH and PCH).

This series of products has been temporarily put into mass production in the scale of 1 million months in March 2021 (sample price 250 yen / single, excluding tax). In addition, new products have also started e-commerce sales, can be purchased through the e-commerce platform Ameya360.

In the future, RoHM also develops 100V and 150V pressure-resistant products for higher-pressure-resistant industrial equipment to expand the lineup of this series, by reducing the power consumption of various applications and achieve their miniaturization to solve environmental protection. problem.

1. achieveindustryUltra-low conductivity resistance

In RoHM developmentindustryIn the advanced bipolar MOSFET, a new process is used, and the ± 40V pressure-resistant product is reduced by up to 61%, and the on-resistance of the NCH portion is also reduced by 39%. Advance power consumption of various devices.

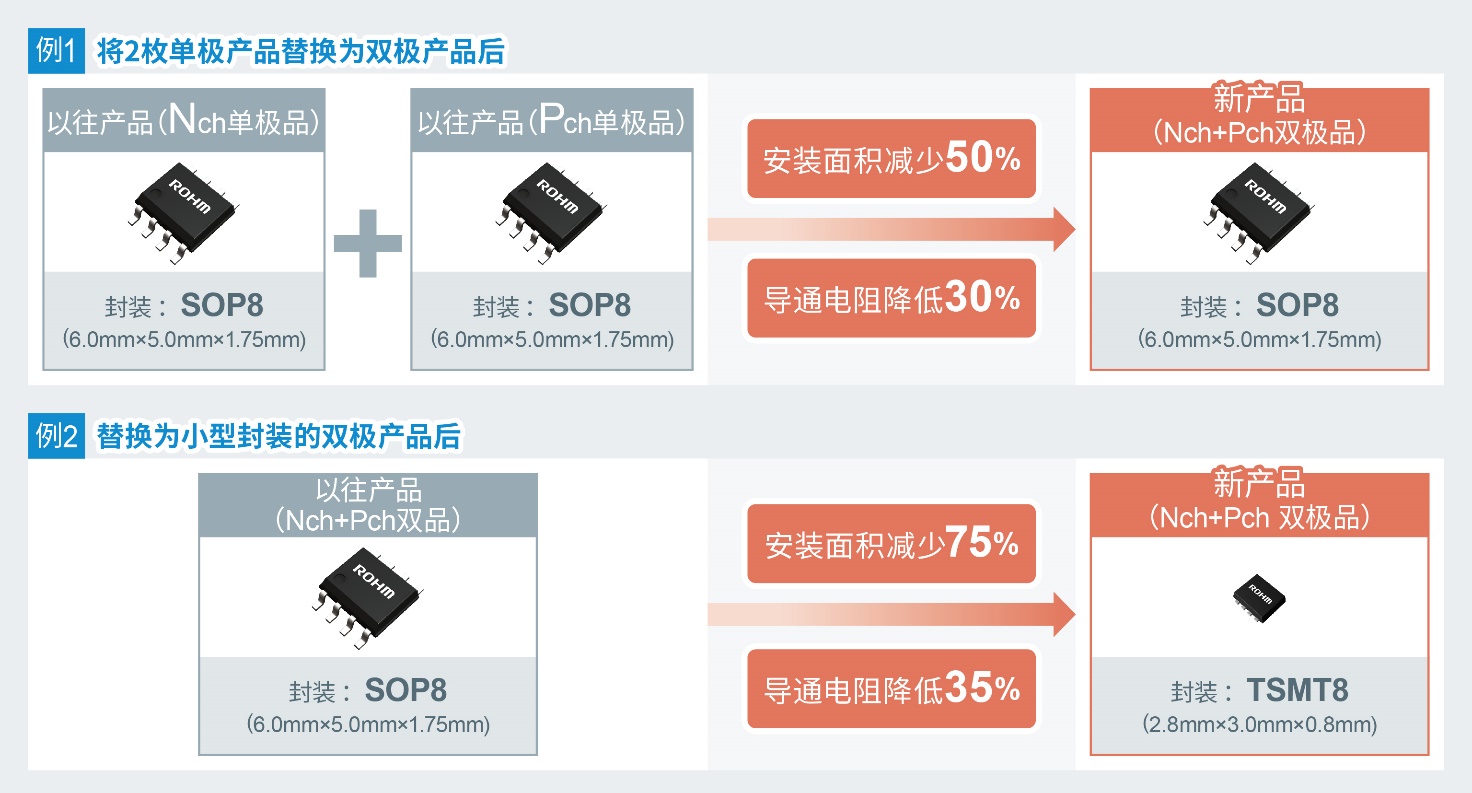

2. Have only the features of only bipolar MOSFETs, help to achieve miniaturization and shortening design cycles

By built-in two devices in one package, it helps to miniaturize the device's miniaturization and reduce device selection. In terms of miniaturization, if a conventional NCH + PCH bid MOSFET (SOP8) is replaced with new products (TSMT8), the installation area can be reduced by 75%.

By using the product with the Rohm single-phase and three-phase brushless motor with a fruitful application performancedriverThe IC is combined to further consider the miniaturization, low power consumption and mute driving of the motor. By providing a combination of bipolar MOSFET series and pre-drive ICs for peripheral circuitry, a motor drive solution that meets its needs and more excellent.

Synthetic example

■ QH8MC5 (± 60V withstand NCH + PCH Double Negotic MOSFET) and BD63001AMUV (three-phase brushless motordriverIC)

■ SH8KB6 (+ 40V withdrawal NCH + NCH Biopathy MOSFET) and BM62300MUV (three-phase brushless motordriverIC)

■ SH8KB6 (+ 40V withstand NCH + NCH Double Negotic MOSFET) and BD63002AMUV (three-phase brushless motordriverIC)

NCH + PCH Biode MOSFET

NCH + NCH bipolar MOSFET

■ FA device,robotWait industrial equipment and fan motor for base station

■ Fan motors for large consumer electronic equipment

* 1) Abbreviation for MOSFET (METAL-OXIDE-SEMICONDUCTOR FIELD EFFECT TRANSISTOR)

Metal oxide-semiconductorField effect transistors is the most commonly used structure in FET. Used as switching elements.

* 2) PCH MOSFET and NCH MOSFET

PCH MOSFET: MOSFETs that are turned on by applying a voltage relative to the source relative to the source.

It is possible to use a voltage driven below the input voltage, so the circuit structure is simple.

Nch MOSFET: By applying phase to the gateMOSFETs are turned on for the source a positive voltage.

Compared to the PCH MOSFET, there is a smaller conduction resistance between the drain, thereby reducing conventional loss.

* 3) Turn on resistance

The resistance value between the drain and the source when MOSFET is started (ON).The smaller this value, the less loss (power loss) at runtime.