News

Infineon launched the 1200 VCoolsic MOSFET M1H chip to enhance the characteristics to further improve the system energy efficiency

- Author:ROGER

- Release on:2022-06-16

On May 10, Infineon Technology Co., Ltd. released a new CoolSicTMTechnology, that is, coolsicTM MOSFET 1200 V M1H.This advanced silicon carbide (SIC) chip is used for the popular Easy module series, as well as a separate packaging -based packaging of .XT interconnection technology. It has a very wide product portfolio. The M1H chip has high flexibility and is suitable for solar systems that must meet peak power demand, such as photovoltaic inverters. At the same time, this chip is also an ideal choice for electric vehicles, energy storage systems and other industrial applications.

The latest progress achieved by CoolSIC technology has increased the grid drive voltage window significantly, thereby reducing the pitch resistance under the established chip area. At the same time, with the expansion of the grid running window, the gate can tolerate the peak of voltage peaks related to the drive and layout, even at a higher switching frequency. In addition to the M1H chip technology, it can also use different packages to achieve higher power density by using different packages to provide more choices for design engineers to help improve their application performance.

Easy module can achieve higher power density

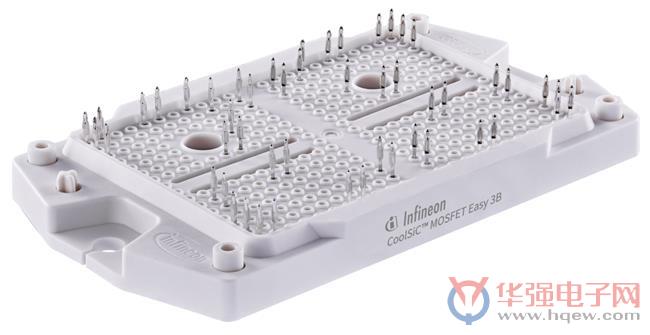

M1H will be integrated into the popular Easy series to further optimize the EASY 1B and 2B modules.also,Infineon will also launch a new product, using the new 1200 V CoolsicTM MOSFET technology and enhancement Easy 3B module. The launch of the size of the new chip has maximized the flexibility and is suitable for a wide range of industrial product portfolios. Using the M1H chip can significantly reduce the pitch resistance of the module, making the device more reliable and efficient.

CoolsicTM MOSFET 1200V Easy 3B

In addition, the maximum knot temperature of the M1H chip is 175 ° C. It has better overload capacity, which can achieve higher power density, and at the same time expand the system security working area.Compared with its predecessor M1 chip, the M1H chip realizes lower internal gate resistance (RG), which is conducive to easily optimizing the switching characteristics. The M1H chip maintains its dynamic characteristics.

Differential packaging with ultra -low -conducting resistance

In addition to integrating the EASY module series, CoolsicTM The MOSFET 1200 V M1H product portfolio also uses TO247-3 and TO247-4 separation packaging. The leading resistance value is extremely low. According to different models, it is divided into 7 MΩ, 14 MΩ and 20 MΩ. The maximum grille source of these new devices is low to -10 V, which improves the grille voltage over pumping and downward, and realizes good cedar anti-avaparon breakdown capabilities and short-circuit tolerance capabilities, which can be easily used for product design.

COOLSIC? MOSFET 1200V TO247-3 and TO247-4

Infineon.xt interconnection technology introduced in D2PAK-7L packaging can now be implemented in To packaging. Compared with the standard interconnection technology, its heat dissipation capacity has increased by more than 30%. Such heat dissipation performance has brought great benefits, which can increase the output power by up to 15%. In addition, it can also increase the frequency of switching and further reduce the passive devices required in applications such as electric vehicles (EV) charging, energy storage or photovoltaic systems, thereby increasing power density and reducing system costs. The .XT interconnection technology can reduce SIC MOSFET knot temperature without changing the operating conditions of the system. Therefore, the system's service life is greatly extended and the power cycle capacity is improved. This is also the key requirement for the equipment such as servo drives.

The newly launched 1200 V CoolSicTM The MOSFET M1H chip will further release the application potential of SIC technology, promote the development and utilization of clean energy globally, and improve energy efficiency.